Modular screen printing solutions that adapt to your processes – rely on 30 years of experience.

Screen printing machines from Alraun Maschinenbau GmbH

Series production with a system – modular, flexible, without special construction

For over 30 years, Alraun Maschinenbau GmbH has stood for high-quality screen printing machines from our own productionWe produce our machines in series, based on a sophisticated modular system.

Thanks to this modular design, our machines can be optimally adapted to different printing requirements and used in different areas – without complex special designs or individual adjustments.

All configurations are within our defined standard range and are ready for immediate use.

Our machines can also be seamlessly integrated into existing customer systems.

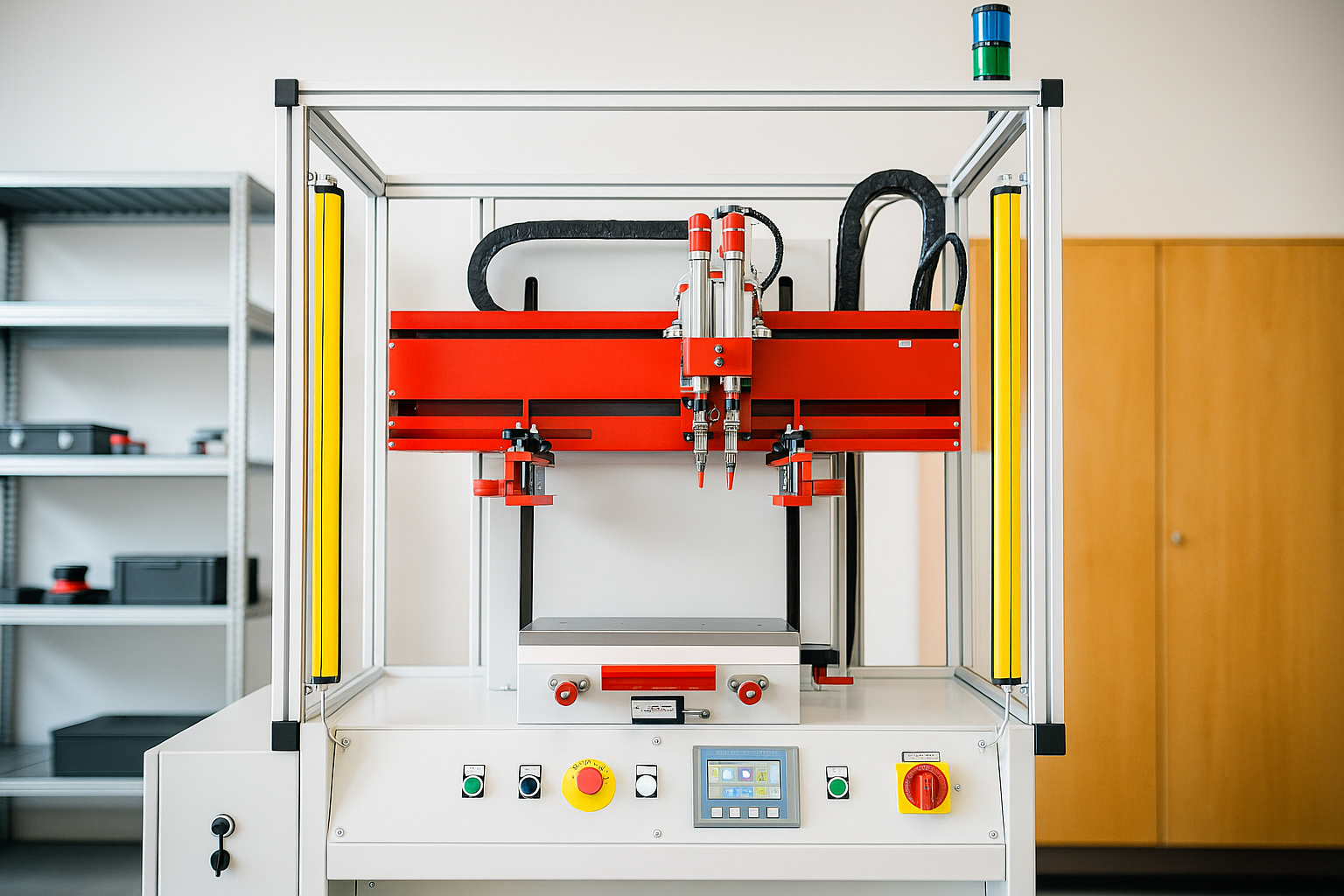

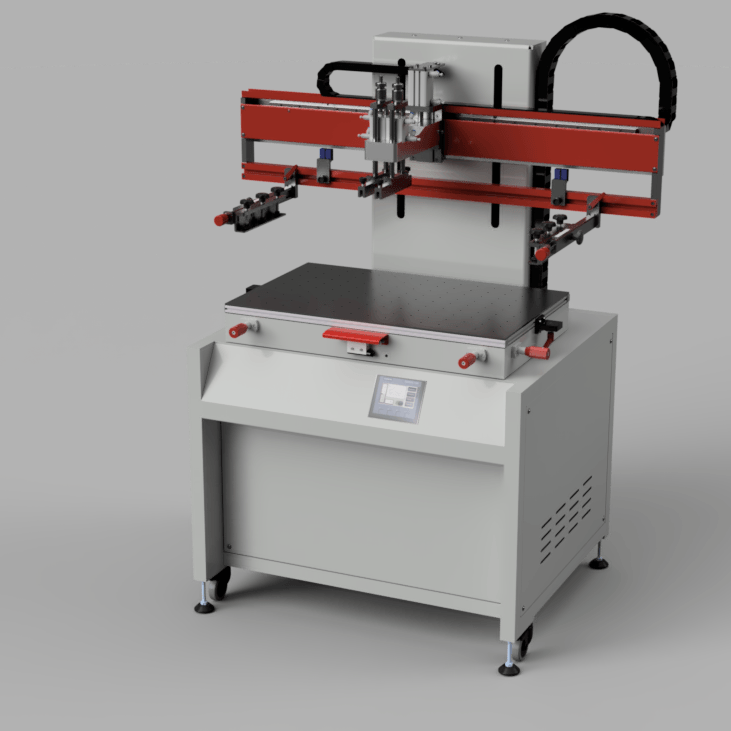

Screen printing machines for flat printing – flexible, precise & efficient

Our screen printing machines for flat printing are the optimal solution for industrial applications – standardized and individually manufactured.

✔ Modular design for maximum flexibility and subsequent expandability

✔ Electronically controlled movements for maximum precision and process reliability

✔ Short setup times & convenient operation via touch display

✔ Fine table adjustment in XYR position for precise adjustment

✔ Servo motors & quick-change squeegee system for efficient production processes

✔ Flexible screen clamping and adjustable squeegee speed

Our flatbed printing machines are available in various printing sizes – from

300 × 500 mm to 450 × 1,200 mm – and can be optimally configured to your requirements.

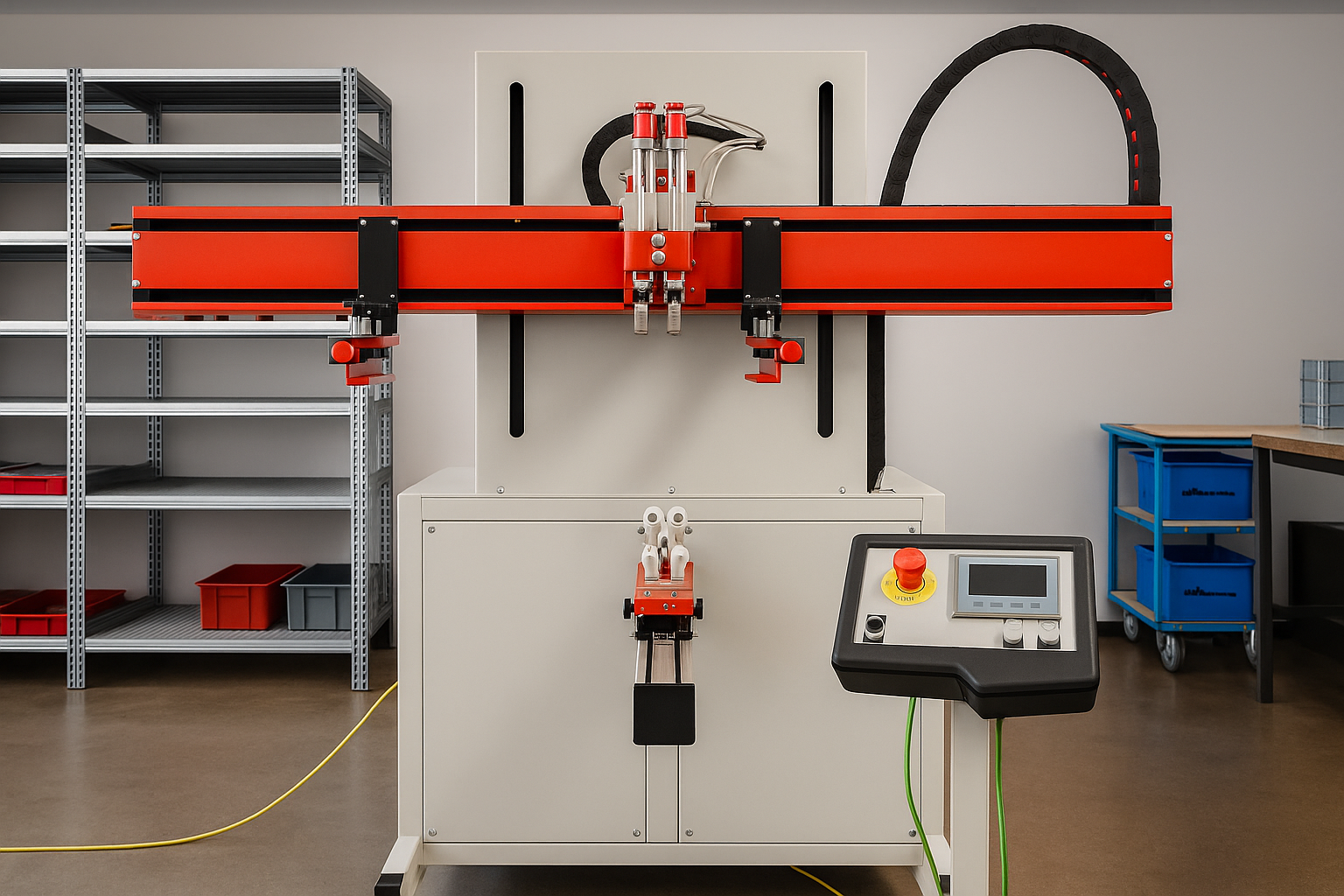

Screen printing machines for round printing – flexible, precise & efficient

Our screen printing machines for round printing are ideal for cylindrical and round workpieces – standardized & individually manufactured.

✔ Modular design for maximum flexibility and subsequent expandability

✔ Electronically controlled movements for maximum precision and process reliability

✔ Short setup times & convenient operation via touch display

✔ Flexible adjustment of the sieve holder movement for different diameters

✔ Laser modules for precise positioning of the print image

✔ Servo motors & quick-change squeegee system for efficient production processes

✔ Flexible screen clamping and adjustable squeegee speed

Our rotary printing machines offer screen holder movements of

183 mm to 933 mm and are suitable for workpieces with diameters of approx.

10 mm to 290 mm.

This allows numerous products such as candles, glasses, tubes and other cylindrical parts to be printed economically and with high quality.

Your benefits at a glance

✅

Modular & flexible

Our screen printing machines are modular in design. They adapt to your production requirements – not the other way around. Adjustments and expansions are possible at any time.

✅

Ready to use & individually configurable

Each machine is factory-tested and ready for immediate use. You can customize the machine precisely to your print sizes and workpieces.

✅

Reliable quality & many years of experience

For over 30 years, customers worldwide have trusted our machines. We develop and manufacture exclusively at our factory in Staig near Ulm.

✅

High precision & process reliability

Electronically controlled movements, servo motors, fine table adjustment in XYR position and a quick-change squeegee system ensure precise and reproducible printing results.

✅

Short setup times & easy operation

Intuitive control via a modern touch display and quick setup reduce downtime and increase your efficiency.

✅

No costly printing tests necessary

Thanks to a well-thought-out system design, immediate and economical use is possible – without complex preliminary tests.

Inquiry screen printing machines

Screen printing machines for round printing – flexible, precise & efficient

Our screen printing machines for round printing are ideal for cylindrical and round workpieces – standardized & individually manufactured.

✔ Modular design for maximum flexibility and subsequent expandability

✔ Electronically controlled movements for maximum precision and process reliability

✔ Short setup times & convenient operation via touch display

✔ Flexible adjustment of the sieve holder movement for different diameters

✔ Laser modules for precise positioning of the print image

✔ Servo motors & quick-change squeegee system for efficient production processes

✔ Flexible screen clamping and adjustable squeegee speed

Our rotary printing machines offer screen holder movements of

183 mm to 933 mm and are suitable for workpieces with diameters of approx.

10 mm to 290 mm.

This allows numerous products such as candles, glasses, tubes and other cylindrical parts to be printed economically and with high quality.

Screen printing machines for flat printing – flexible, precise & efficient

Our screen printing machines for flat printing are the optimal solution for industrial applications – standardized and individually manufactured.

✔ Modular design for maximum flexibility and subsequent expandability

✔ Electronically controlled movements for maximum precision and process reliability

✔ Short setup times & convenient operation via touch display

✔ Fine table adjustment in XYR position for precise adjustment

✔ Servo motors & quick-change squeegee system for efficient production processes

✔ Flexible screen clamping and adjustable squeegee speed

Our flatbed printing machines are available in various printing sizes – from

300 × 500 mm to 450 × 1,200 mm – and can be optimally configured to your requirements.