Drying systems

& Belt dryers

– Alraun Maschinenbau

Modular drying solutions that adapt to your processes – rely on 30 years of experience.

Send us your request and you will receive your individual offer within 8 hours.

Why companies choose Alraun

Over 30 years of experience

in mechanical engineering.

10000 realized

Drying systems

6 weeks Delivery time

& Spare parts in stock

Planning, manufacturing &

service from a single source

Benefit from over 30 years of experience and tailor-made solutions.

Applications: Belt dryers, continuous dryers & tunnel dryers

The right solution for every process

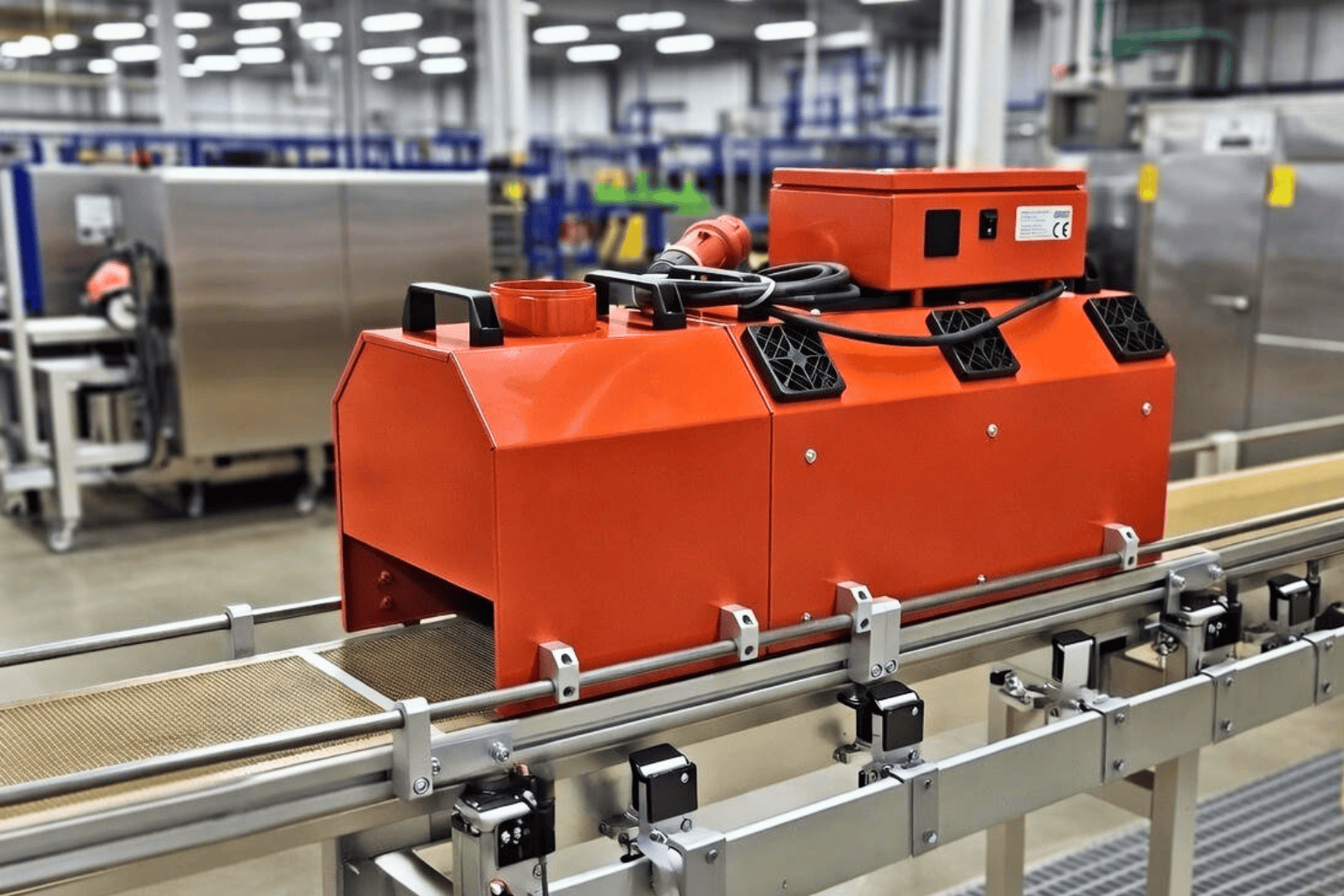

Our belt dryers, continuous dryers, and tunnel dryers are not standard units, but precisely engineered industrial dryers designed for 24/7 operation. They impress with maximum process stability, energy efficiency, and scalability. Ideal for all applications where drying, curing, and fixing are critical.

Belt dryer

Efficient solution for bulk materials and continuous drying processes:

- Even and gentle drying at

high throughput

- High energy efficiency and stable processes in

Continuous operation

- Process optimization for

Curing and fixing of materials

- Process optimization for

Curing and fixing of materials

- High energy efficiency and stable processes in

Continuous operation

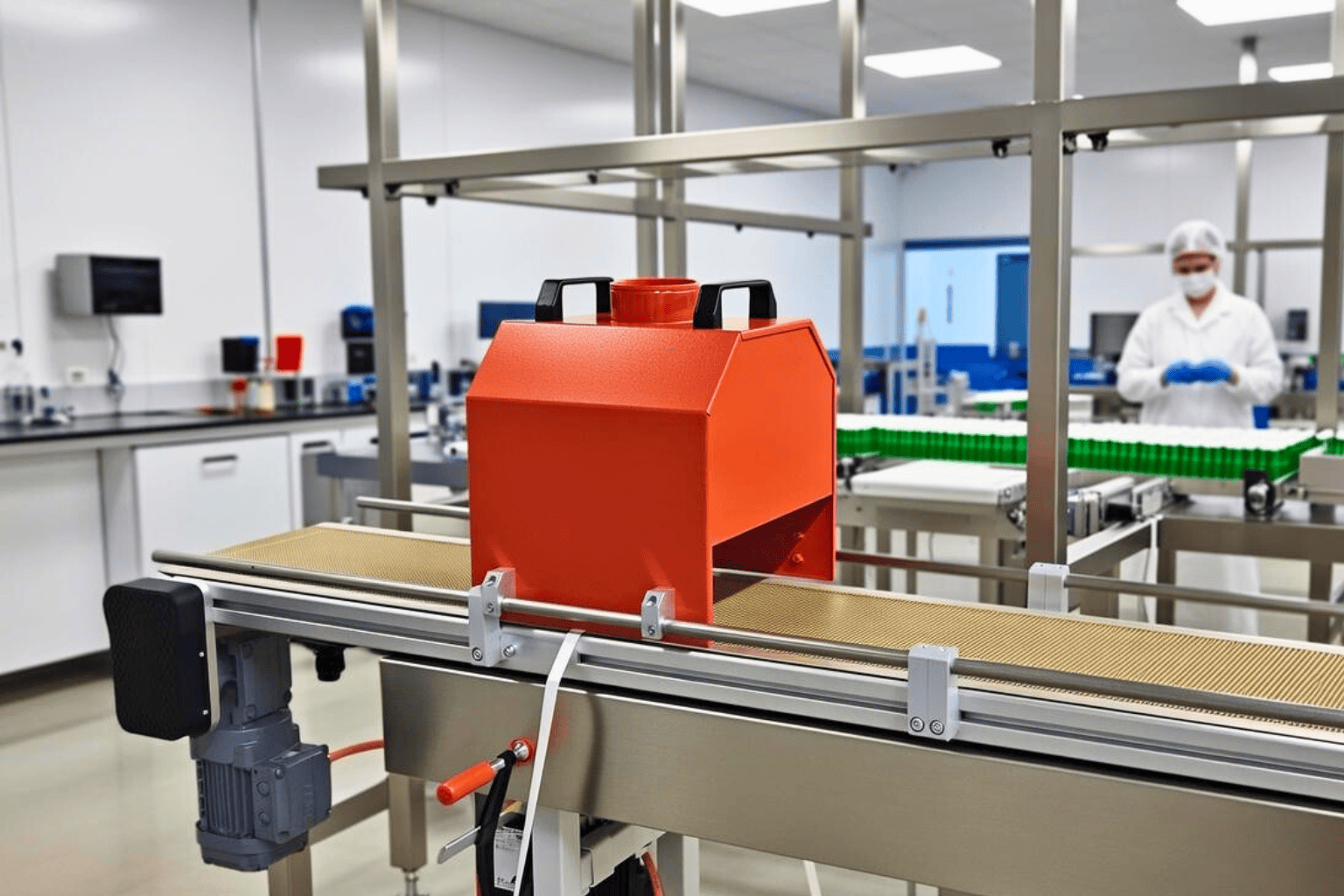

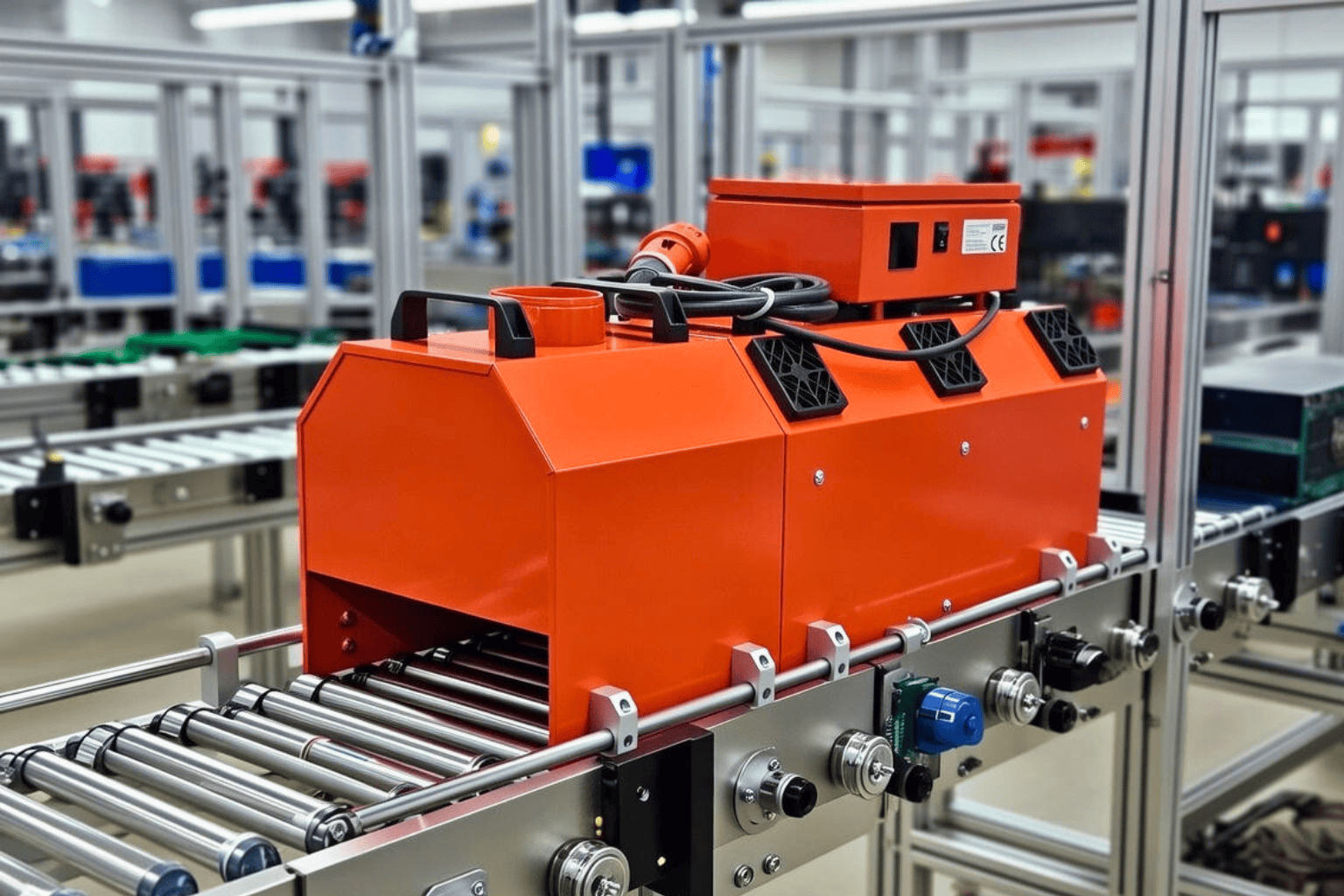

Continuous dryer

Compact systems for precise and reproducible drying:

- Ideal for technical components and

Series production

- Space-saving design with high process reliability

- Seamless

integration in existing

Production lines

- Precise temperature control

for fixing coatings

- Precise temperature control

for fixing coatings

- Seamless

integration in existing

Production lines

- Space-saving design with high process reliability

Tunnel dryers & oven systems

High-performance systems for demanding industrial processes:

- Designed for

high production volumes and continuous operation

- constant

Temperature and airflow for reproducible results

- Proven in demanding environments

thermal processes such as hardening, drying and fixing

- Proven in demanding environments

thermal processes such as hardening, drying and fixing

- constant

Temperature and airflow for reproducible results

Find the right belt dryer, continuous dryer or tunnel dryer for your application – we configure it exactly to your requirements.

Technical advantages

This is what distinguishes mandrake from standard dryers.

Modular building block system

Assemble your continuous dryer, belt dryer or tunnel dryer exactly to your needs.

Drying widths of 30, 50, 70 or 90 cm and modular lengths (each heated unit 60 cm) allow for any total length.

Subsequent expansions are possible at any time – your drying system grows with your production.

Selectable drying technologies for optimal results

Choose the right technology:

• IInfrared dryer (IR): – Medium and long wave, pure radiation energy without air movement,

up to 250 °C, digitally controlled

– ideal for fast and gentle surface drying.

• Warm air dryerr – uniform volume flow

(0.5–0.75 m/s), up to 150 °C, digitally controlled

– perfect for the homogeneous drying of your sensitive products such as herbs, hemp or grains.

Precise and reproducible process control

Utilize independent power and control electronics in each drying tunnel for maximum accuracy.

Exhaust air modules (30 cm length, connection Ø 100 mm) reliably remove moisture and gases.

Adjust the passage height to 100 mm as standard, or optionally to 25, 30 or 40 cm.

– for maximum flexibility with your different workpieces.

Ideal for fixing and curing surface coatings.

Conveyor belts & belt technology – flexible and adaptable

Choose the appropriate belt conveyor in lengths from 200 to 600 cm and widths from 30 to 90 cm.

Set up your conveyor belt in a height-adjustable, tiltable and mobile position on casters –

This allows you to place it exactly where you need it, regardless of location.

Benefit from belt options such as food-safe, closed,

Teflon-coated mesh tape or glass mesh reinforced – optimally tailored to your application.

Energy efficiency and durable industrial quality

Reduce your energy costs through optimized heat utilization and minimal downtime.

Rely on robust steel construction, maintenance-friendly design and long-term spare parts availability.

Your industrial dryer “Made in Germany” is a safe investment for reliable continuous use.

Find the right belt dryer, continuous dryer or tunnel dryer for your application – we configure it exactly to your requirements.

Application areas of our industrial drying systems

Our drying systems are used across all industries wherever materials, components, or products need to be dried in a controlled, reproducible, and energy-efficient manner. Thanks to their modular design, belt dryers, continuous dryers, and tunnel dryers can be precisely tailored to the requirements of your specific industry.

Industry & Production

Our drying systems ensure stable, consistent, and reproducible results in industrial production processes – even with varying materials and high throughput. They are designed for continuous 24/7 operation and can be seamlessly integrated into existing production lines.

Process focus areas:

Production & manufacturing technology · Inline process technology · Process stabilization · Curing & fixing

Typical applications:

Industrial drying, surface drying, technical components, continuous processes

Pharma & Life Sciences

Gentle, reproducible drying processes for sensitive materials with constant process parameters – ideal for quality-critical applications in pharmaceuticals, medical technology and life sciences.

Process focus areas:

Thermal process engineering · Curing and fixing processes · Process stabilization · Precision manufacturing · Material processing

Typical applications:

Pharmaceutical materials · Medical technology · Laboratory samples · Drug drying · Sterile processes

Agriculture & Food Raw Materials

High-performance drying solutions for grains, herbs, and plant-based raw materials. Our belt and continuous dryers ensure uniform, material-specific drying with high energy efficiency and process reliability – for optimal quality and shelf life.

Process focus areas:

Materials processing · Thermal process technology · Post-treatment & finishing

Typical applications:

Drying grain, drying herbs, agricultural commodities, biomass

Printing & Electronics Industry

Our drying systems ensure uniform drying of inks, varnishes and functional surfaces in the printing and electronics industries – with short throughput times and stable integration into existing production processes.

Process focus areas:

Inline processes · Curing & fixing processes · Surface & coating processes

Typical applications:

Paint drying, screen printing, printed circuit boards, electronic components, surface drying, functional coatings

Environmental Engineering & Wastewater Management

High-performance belt dryers for drying sewage sludge and industrial residues. They enable energy-efficient volume and weight reduction and ensure economical and sustainable disposal processes.

Process focus areas:

Thermal process engineering · Material processing · Post-treatment & finishing · Inline process engineering

Typical applications:

Sewage sludge drying · Belt dryers · Disposal processes · Industrial residues · Energy-efficient drying

Request a suitable drying solution for your application now.

Inquire now

Secure better delivery times and

The optimal drying solution for your process.

You will receive your personalized offer within 8 hours.

– non-binding and individually tailored.

Those who inquire early avoid bottlenecks and start with the best interpretation.